Oil & Gas Solutions

A Step Towards Zero Flaring: Flare Gas to Power Solutions

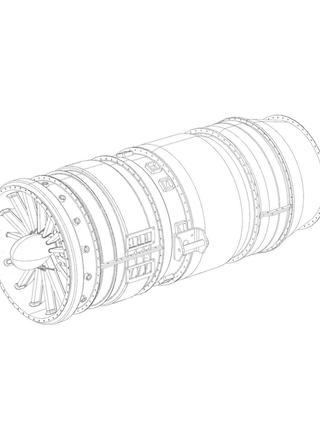

The OPRA OP16 Gas Turbine enables...

- Accept or reject up to 100% load

- Resistant to air and fuel contaminations

- Ability to tolerate H2S content up to 7%* in the fuel

- Operate with dynamically changing LHV

- Seamless dual fuel operation

- Long service intervals: one intervention per year

- 42,500 operating hours between overhauls

- Proven flare gas technology

- Successful certifications (DNV, API, ISO)

- Compact, lightweight, modular package design

*The number provided is subject to change depending on the specific project and fuel composition.

The OP16 has the capability to efficiently convert flare gas into valuable energy, even when dealing with challenging fuel composition. Flare or asssociated gases are frequently contaminated with substances like H2S or have a high concentration of heavy hydrocarbons, posing significant obstacles to their utilization for power generation. However, the OPRA OP16 Gas Turbine excels in harnessing these demanding gases, accommodating up to 7% H2S contamination, and producing clean electricity directly, eliminating the necessity for additional gas treatment processes.

The OP16 Gas Turbines provide reliable and continuous power to run various equipment and systems, including drilling rigs, production platforms, pipelines, and processing facilities. The OP16 offers high power output and operational flexibility, making it suitable for remote locations with limited access to the grid.

Refineries require large amounts of heat, steam and electricity in their processes. In many cases off-gases are produced as a byproduct of refinery operations. The OPRA OP16 Gas Turbine can use challenging gases as fuel for various purposes such as generating electricity, heat or steam for process applications.

The OP16 Gas Turbine has a compact design, making it suitable for offshore platforms with limited space availability. The OP16 combines extremely high-power density with a reliable, low- maintenance operation. It meets the high standards for offshore and marine applications. The OP16 is installed in compact enclosures or modules, reducing the footprint and allowing for efficient use of deck space.

Tanker ships play a vital role in transporting substantial volumes of crude oil. During the transportation process, certain components of the crude oil tend to "gas out" forming Volatile Organic Compounds (VOCs). These VOCs must be effectively eliminated from the tanks. Rather than resorting to flaring these VOCs, the OPRA OP16 Gas Turbine offers a valuable solution by efficiently utilizing them as a fuel source for power generation.

The OPRA OP16 Gas Turbine combines extremely high-power density with a high reliability and availability, well-established maintenance and monitoring practices. The OP16 meets the high standards for FPSO (Floating Production Storage and Offloading), offshore and marine applications.